Acrylic vs Polycarbonate: Which is Better for Information Display Windows? When it comes to choosing materials for information display windows, Acrylic and Polycarbonate are two of the most popular options. Both materials offer distinct advantages, making them ideal for specific applications.

Choosing between polycarbonate and acrylic depends on the specific requirements of your application. Here are some factors to consider when deciding which material to use:

Acrylic (PMMA)

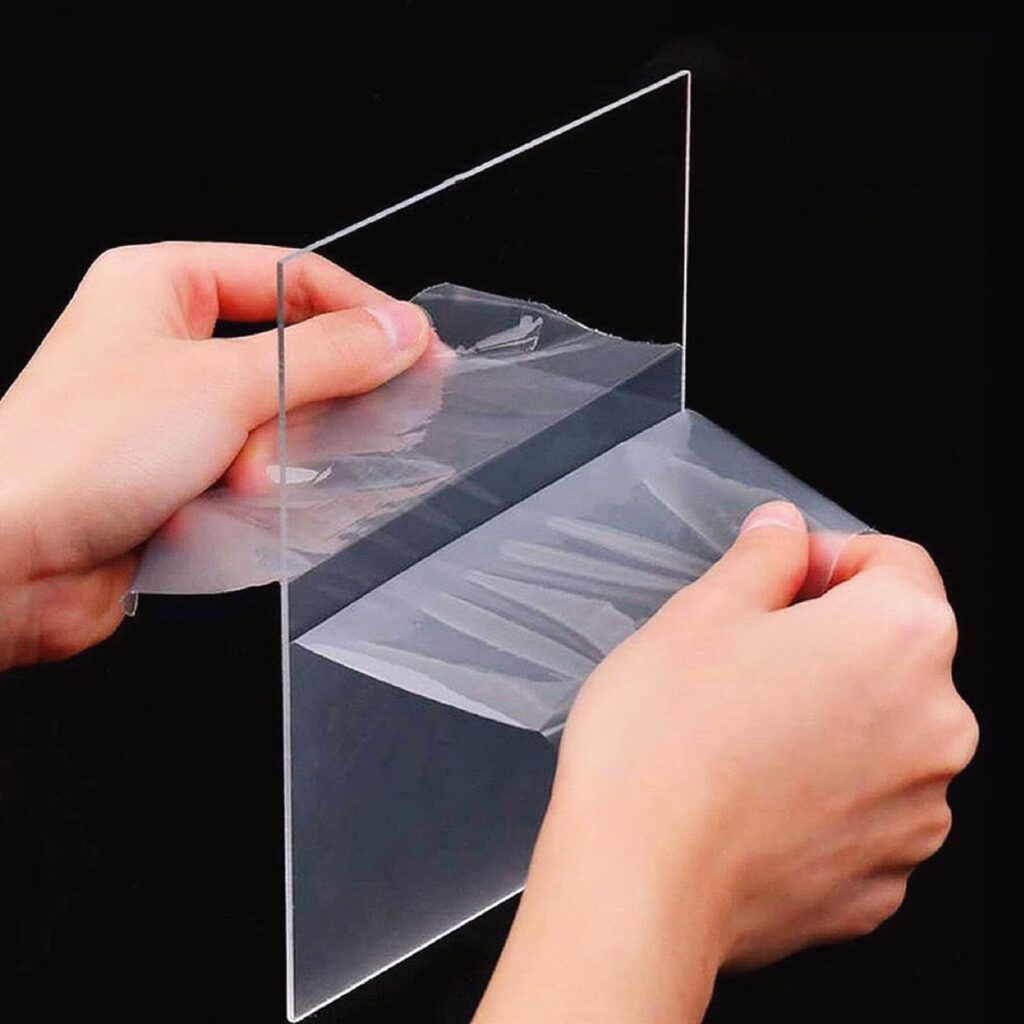

Acrylic, is a transparent thermoplastic that is widely used in various industries. It’s a popular choice for display windows due to its optical clarity and scratch-resistant properties.

Pros of Acrylic:

- High Optical Clarity: Acrylic offers excellent light transmission (92% or more), making it ideal for display windows where clarity is essential.

- Scratch Resistance: Compared to polycarbonate, acrylic is more resistant to scratching and abrasion.

- Cost-Effective: Acrylic is generally less expensive than polycarbonate, making it an affordable option for many applications.

- UV Stability: Acrylic has good UV resistance, which prevents it from yellowing over time when exposed to sunlight, making it suitable for outdoor displays.

- Lightweight: Acrylic is lighter than glass, which can reduce the overall weight of display units.

Cons of Acrylic:

- Brittleness: Acrylic is more prone to cracking or shattering under impact, especially compared to polycarbonate.

- Limited Impact Resistance: While stronger than glass, acrylic is not as impact-resistant as polycarbonate.

- Less Flexible: Acrylic has lower flexibility, making it more difficult to mould into complex shapes without breaking.

Applications Suited to Acrylic:

- Retail Displays: Its optical clarity and scratch resistance make it perfect for retail environment’s

- Exhibition Windows: Acrylic’s ability to resist yellowing and maintain clarity makes it suitable for museum or exhibition displays.

- Indoor Signage: Cost-effectiveness and lightweight nature are ideal for indoor information windows and signs.

Polycarbonate (PC)

Polycarbonate is a highly durable thermoplastic known for its impact resistance and versatility. It’s widely used in applications that require high strength and protection.

Pros of Polycarbonate:

- High Impact Resistance: Polycarbonate is up to 250 times stronger than glass and significantly more impact-resistant than acrylic, making it ideal for environments where durability is key.

- Heat Resistance: Polycarbonate can withstand higher temperatures without deforming, which is beneficial for outdoor or industrial applications.

- Flexibility: Polycarbonate is more flexible and can be moulded into complex shapes without cracking.

- Security: Because of its strength, polycarbonate is often used in security windows or vandal-resistant applications.

- Lightweight: Like acrylic, polycarbonate is lighter than glass, making it easy to handle and install.

Cons of Polycarbonate:

- Lower Scratch Resistance: Polycarbonate scratches more easily than acrylic, though it can be coated with scratch-resistant coatings (such as those offered by Panel Graphic).

- Higher Cost: Polycarbonate tends to be more expensive than acrylic, especially with additional coatings.

- Susceptible to UV Damage: Without proper UV protection, polycarbonate can yellow over time, making it less suitable for long-term outdoor use unless coated with UV-resistant finishes.

Applications Suited to Polycarbonate:

- Outdoor Information Displays: Polycarbonate’s strength and heat resistance make it perfect for outdoor displays that may face impact or extreme weather.

- Security Windows: Due to its durability, polycarbonate is often used in security windows where high impact resistance is necessary.

- Industrial Settings: In environments that require both durability and heat resistance, polycarbonate is the go-to material.

Why Choose One Over the Other?

When deciding between acrylic and polycarbonate for information display windows, consider the specific needs of your project:

- Optical Clarity: If maintaining high optical clarity over time is important, acrylic may be the better option, especially for indoor applications.

- Impact Resistance: For environments where the display may face physical impact or extreme conditions (like outdoor or industrial settings), polycarbonate is the superior choice due to its toughness.

- Cost: Acrylic is often chosen for cost-sensitive projects that don’t require extreme durability.

- Scratch Resistance: If scratch resistance is a key factor, acrylic is the better choice. However, polycarbonate can be coated with specialised scratch-resistant coatings to enhance its durability.

- UV Exposure: For outdoor displays, acrylic is naturally more UV-resistant, but polycarbonate can also be treated to protect against UV damage.

Both acrylic and polycarbonate offer unique advantages depending on the application. Acrylic is ideal for situations where optical clarity and scratch resistance are the top priorities, while polycarbonate excels in environments requiring durability and impact resistance.

By understanding the pros and cons of each material, you can make an informed decision that ensures the best performance for your information display windows.

Why Choose Panel Graphic?

We strongly believe there’s strength in knowledge.

With over 100 years expertise in dealing with plastics, we are more than experienced to deal with any anti reflective plastic needs you may have.