What is LiDAR?

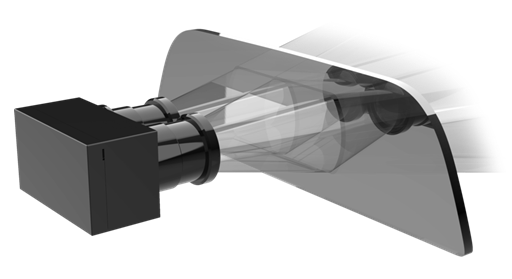

LiDAR, Light Detection and Ranging, is a remote-sensing that uses a laser beam to get information about surrounding objects.

It allows mapping tools to examine the environment providing accuracy, precision, and flexibility.

What are LiDAR Cover Lenses?

LiDAR Cover Lenses are used to prevent obstruction of laser light waves.

LiDAR systems may be embedded in:

- Automotive grilles

- Bumper fascia’s

- Headlights

This, in turn, allows them to be exposed to:

- Harsh weather conditions

- Road chemicals & debris

All of which affect their optical transparency and durability.

A suitable solution would be to protect the sensitive cameras with high transparency plastics that have good chemical resistance and long term performance.

For example:

By using Polycarbonate you have a strong material substrate that enables high impact resistance. Along with creative manufacturing (shaping/moulding) capabilities.

This material used in conjunction with surface treatments like Optiguard™ Clear hard coating create a final product that will protect the laser scanners and also offer enhanced transmission levels and extremely durable long term optical performance.

Optical transmission can be improved by the surface application of Optiguard™ hard coatings.

This improvement is also visible to the human eye.

Polycarbonate has become a great option in high specification applications requiring high transmission requirements.

Its superior surface hardness ensures the optical improvements are maintained over long periods of product use.

Benefits of polycarbonate for LiDAR applications

| Effect | Direct Benefit |

|---|---|

| Reduction in surface energy | Enables water shedding characteristics |

| Hydrophobic surface | Easy clean finish |

| Improvement of surface roughness refraction | Reduces and prevents unwanted light |

| Superior surface hardness (6-8H) | Preventing damage to surface, thus maintaining optical performance |

| High chemical resistance | Long term performance in demanding environments |

Find out more about our Optiguard range.

Benefits of polycarbonate plastic over acrylic (PMMA)

- Significantly stronger with:

- 250x the impact resistance of glass

- 30x the strength of acrylic

- Working temperature of 240 degrees – Giving it a low level of flammability

- Resists chipping & cracking

- Corrosion Resistant when used in chemical applications

- Will not crack when drilled or machined

- Can be formed without the need of introducing heat

Whilst polycarbonate seems like the right solution, some may choose to use acrylic:

What are the advantages of acrylic?

- It’s lightweight in comparison to polycarbonate

- Easiest to process, it has much better machining properties

- Can be thermoformed with reduced to no risk of stress cracking

- High transmission rate, close to that of 92%

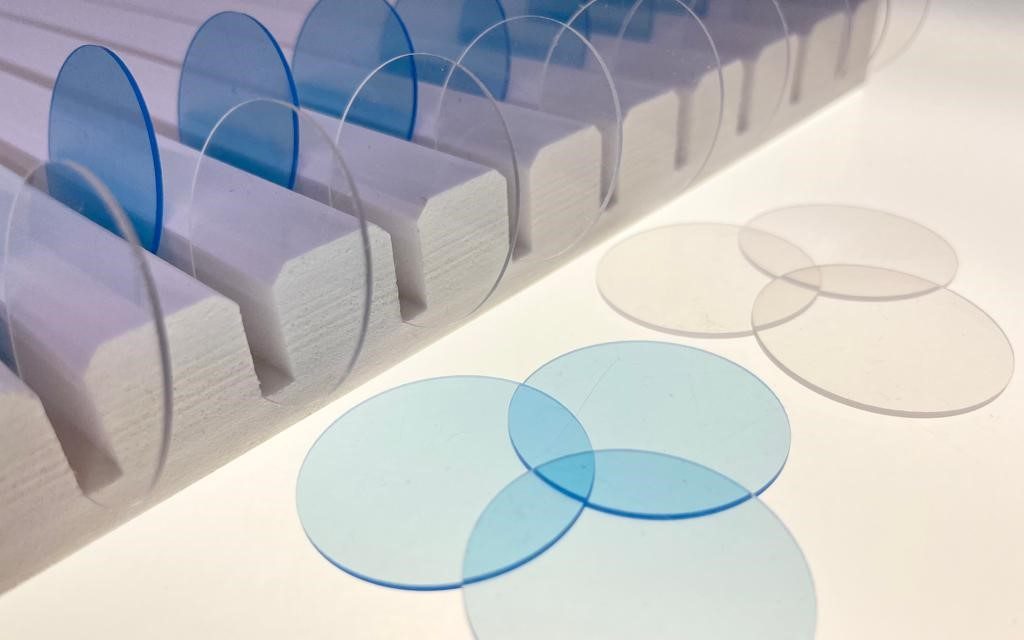

LiDAR Cover Lens Samples

We have samples available in acrylic & polycarbonate.

Both with a clear hard coat applied to both sides.

Sizes available are 20mm & 40mm diameter.

To request a sample, please get in touch.